Stainless Steel Flange Manufacturer in Vapi

Stainless Steel Flange Supplier in Thalassery, SS Flange Manufacturer in Vapi

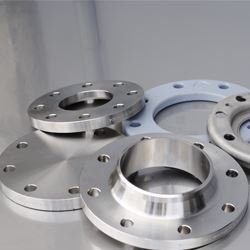

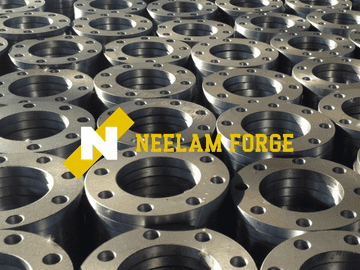

Neelam Forge India one of the prime reputable Stainless Steel Flange Manufacturers in Vapi. Our SS Socket Weld Flanges are made using super-austenitic materials of low carbon content to enhance strength. These SS Reducing Flanges provides good corrosion resistance, are high in demands. The SS Ring Joint Flanges are usefull in various applications in Vapi in piping end connections and perform great in welding, bolting, and related maintenance tasks.

TABLE OF CONTENTS

SS Flange Manufacturers, ASME SA182 Stainless Steel Flange Price, SS Flange Supplier, Stainless Steel Flange Manufacturer in Vapi

Neelam Forge India is one of a few of the most reputed firms that deal in manufacturing, supplying, and trading of Stainless Steel Flange in Vapi. We have led to an increase in the demands for stainless steel products. As one of the largest and reliable Stainless Steel Flange Supplier, we have earned vast experience in fulfilling exacting requirements in the Chemicals and Paper Industries of Vapi. For more information on Stainless Steel Flanges or to request a quote for a custom SS flange, please contact us at sales@neelamforgeindia.com.

Standard Specification of Stainless Steel PN10 Flanges

| Manufacturer Specifications | ASTM A182 Stainless Steel Flanges |

| Types Of SS Flanges | Blind/ Slip On/ Weld Neck/ Socket Weld/ RTJ/ Lap Joint/ Threaded/ Reducing Flanges |

| SS Flange Dimensions | EN 1092-1/ EN 1092-2/ DIN 2501/ DIN 2527 |

| Size | 1" (12 NB) to 48" (1000NB) DN10~DN5000 |

| Face Type | Ring Type Joint (RTJ)/ Raised Face/ Flat Face |

| Available Grades | ASTM A182 F304 & F304L/ ASTM A182 F316 & F316L/ ASTM A182. |

| Flange Forging Methods | Forging/ Casting/ Rolling And Cutting |

| Pressure Rating | Class 150/ Class 300/ Class 400/ Class 600/ Class 600/ Class 900/ Class 1500/ Class 2500. |

| Pressure Calculation in DIN | PN6, PN10, PN25, PN40, PN64 | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar. |

Stainless Steel Pipe Flanges Grades Available in Vapi

SS Socketweld Flange Supplier - Pressure Ratings

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

SAE Stainless Steel Flange Supplier in Vapi at discounted Price, Types of Stainless Steel Flanges

Equivalent Grades of Stainless Steel Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4301 | S30409 | – | – | – | – | – |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | – | – | – | – | – |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| SS 317 | 1.4449 | S31700 | SUS 317 | – | – | – | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | – | – | – | X2CrNiMo18-15-4 |

| SS 321 | 1.4541 | S32100 | SUS 321 | – | – | – | X6CrNiTi18-10 |

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

Stainless Steel Flanges Chemical Composition

| Type | Carbon | Manganese | Phosphorus | Sulphur | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| 302 | 0.15 | 2.00 | 0.045 | 0.030 | 1.00 | 17.00/19.00 | 8.00/10.00 | – |

| 309 | 0.20 | 2.00 | 0.045 | 0.030 | 1.00 | 22.00/24.00 | 12.00/15.00 | – |

| 304L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/12.00 | – |

| 304* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/10.50 | – |

| 309S | 0.08 | 2.00 | 0.045 | – | 1.00 | 22.00/24.00 | – | – |

| 317 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00/1.00 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 310 | 0.25 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 347 | 0.08 | 2.00 | 0.040 | 0.030 | 0.5/1.00 | 17.00/19.00 | 9.00/12.00 | 0.5/0.75 |

| 317L | 0.03 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 321 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 17.00/19.00 | 9.00/12.00 | 0.75/0.75 |

Stainless Steel Flanges Supplier - Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Heat Treating Temperature, min or range (°C) |

|---|---|---|---|---|

| 304/304H | 515 min | 205 min | 28% | 1040 |

| 304L | 485 min | 170 min | 28% | 1040 |

| 310/310S | 515 min | 205 min | 28% | 1040 |

| 316/316H | 515 min | 205 min | 28% | 1040 |

| 316L | 485 min | 170 min | 28% | 1040 |

| 316Ti | 515 min | 205 min | 28% | 1040 |

| 317/317L | 515 min | 205 min | 28% | 1040 |

| 321/321H | 515 min | 205 min | 28% | 1040-1050 |

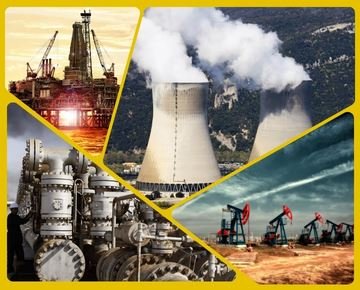

Application Of Stainless Steel Flanges

Packing Of Stainless Steel Flange

The packing is done export-worthy, making sure the client receives our flanges in good condition.

Neelam Forge India is a ISO certified Stainless Steel Flange Manufacturer and Supplier in Vapi.- Neelam Forge India

Different Types Of SS Flanges Stock Available in Vapi

SS Flange Manufacturer and Supplier in Indian Cities

Neelam Forge India is a popular Manufacturer and Supplier of SS Flanges. With a major presence in Vapi and other cities and a approved supplier of SS Flanges in vapi, we continue to be in a leading position in supplying durable, robust, and high-quality Stainless Steel Orifice Flanges to customers across India.